RAL 9005 jet black smooth satin gloss ESD

Options

Dark Blue Glaze

Options

Black-grey heat-resistant

Options

DB 702 Smooth Matt

Options

DB 702 Fine Structure Matt

Options

FOR POWDER COATING

SPECIAL POWDER COATINGS & SPECIAL COLORS

Our online offering is aimed at small to medium-sized coating projects. If you require larger powder quantities (10 kg or more), we'll be happy to provide you with a customized quote. With custom colors from Pulverkönig, you can achieve a customized finish for your workpiece!

We source our special colors from various manufacturers and can therefore offer a wide variety of specialty colors for powder coating. Specialty powder coatings offer enhanced properties and applications compared to conventional powder coatings. They are developed for specific requirements such as high heat resistance, chemical resistance, increased mechanical strength, UV protection, and more. Here are some tips and general information that may be useful when working with specialty powder coatings:

Determining requirements: Consider the specific requirements of your application, such as environmental conditions, mechanical loads and desired appearance.

Preparation and application

Surface preparation: Thorough cleaning and preparation of the surface is crucial for good adhesion and a high-quality finish.

Proper Application: Follow the manufacturer's instructions for application, including recommended film thickness and curing temperatures.

Curing and post-treatment

Curing process: Specialty powder coatings may require specific curing conditions. Ensure your oven can consistently reach and maintain the required temperatures.

Follow-up inspection: Check the coated part for quality, adhesion and desired properties.

Safety and environmental protection

Safety measures: Use personal protective equipment (PPE) and ensure adequate ventilation in the work area.

Environmental compatibility: Observe the disposal regulations for excess powder and cleaning agents.

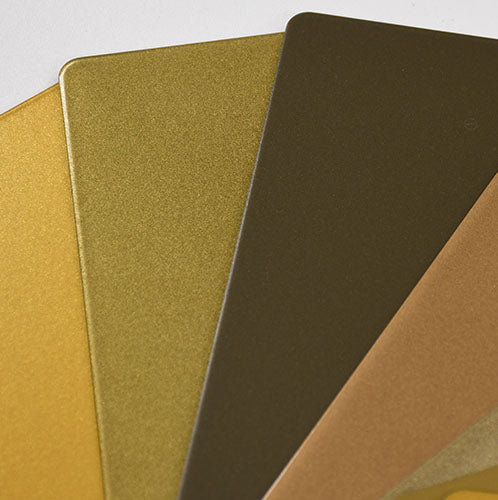

Metallic effects and textures: Some specialty powder coatings offer special effects and textures for decorative applications.

Storage and shelf life

Storage conditions: Store powder coatings in a cool, dry place to maintain their quality and durability.

Expiry date: Please note the expiry date of the product, as the properties of the varnish may deteriorate over time.

Technical support

Manufacturer support: Use technical data sheets and the manufacturer's customer service for specific questions and support. By following these tips and information, you can maximize the benefits of specialty powder coatings and achieve high-quality coatings.